Engineered for demanding applications that require heavy cuts, large volume millwork, thick materials, and a rigid steel tubular frame, the Apex 3R CNC router has become a very popular. Designed to be able to cut thick plywood, melamine, plastics, and non ferrous metals all day long, the Apex 3R is built to last. Additional gantry clearance, a 13 HP spindle, surface probing and pop up pin options help the Apex 3R user produce accurate parts day after day.

robust all-steel construction

and thick tube steel frame

Versatile spindle options up to

32K RPM and 13.3 HP,

complemented by single or dual

knife choices

High-precision gearbox and

AC servo system on helical

rack

All-Steel Construction:

The sturdy base frame is manufactured using thick tube steel, this robust design provides the stability and support for the machine to excel in cutting applications. With the ability to cut through materials up to 5 inches thick, the Apex 3R CNC router ensures minimal vibration and tight control during the entire cutting process, resulting in precision and accuracy that is unmatched in its class.

Multiple Cutting Technologies:

Collet and ATC spindle options ranging from 24-32K RPM and up to 13.3 HP. Single or dual knives options: automatic drag knife changer, pneumatic or electric oscillating knife allowing the Apex 3R CNC router to deliver exceptional cutting capacity and speed on a wide variety of materials and applications.

Precise Cut Quality:

A high-precision gearbox and a tightly tuned AC servo motor system on 25 mm linear rails with a helical rack. This configuration ensures very low backlash and delivers pristine cut quality with precise accuracy.

| Model | Inches | Metric |

| 103 | 53” x 100” | 1346mm x 2540mm |

| 204 | 63” x 121” | 1600mm x 3073mm |

| 304 | 83” x 121” | 2108mm x 3073mm |

Other sizes available

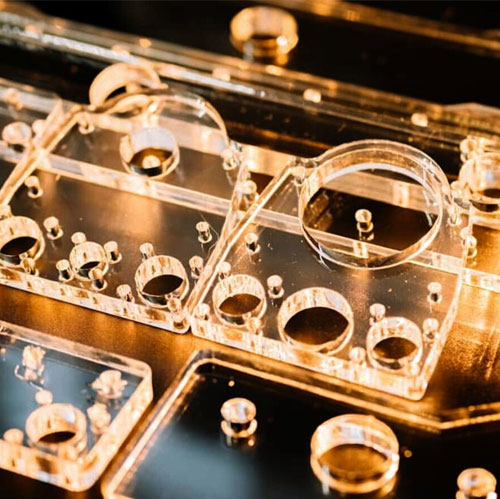

The Apex 3R CNC Router is adept at cutting a variety of materials with precision. It smoothly handles plastics, MDF, plywood, melamine, and foam board. Its capabilities extend to aluminum and ACM, making it perfect for tasks in sign manufacturing, plastic/acrylic machining, and woodworking.

MDF

Plywood

Plastics

Melamine

Foam Board

Aluminum

ACM

Renowned for its versatility and precision, the Apex 3R CNC Router is an essential tool in various industry segments. In Furniture Building, it enables the creation of intricate and durable pieces. Its efficiency in Plastic or Acrylic Machining ensures precise and smooth finishes, vital for quality products. In the realms of Woodworking or Millwork, the Apex3R’s capability to execute detailed cuts and carvings is invaluable. These industries depend on the Apex 3R for its consistent performance and adaptability across diverse materials and complex projects.

Furniture Building

Plastics / Acrylic Machining

Woodworking / Millwork

Get a detailed look at the APEX3R Router with our downloadable machine layout. Easy and quick, it’s your first step to seamless integration!

We can package in the CAD/CAM software of your choice with your machine purchase, or you are free to use an existing system at your company or purchase CAD/CAM separately. We believe that freedom to choose CAD/CAM (independent of the machine) gives our customers the most flexibility.

Sign-up for our newsletter!

Machines

Contact Us

Copyright Mikon Machinery ® LLC 2024. All Rights Reserved. | Designed by CNC Marketer